Ideas

Design

Creative

Old office since 1878 till now.

Two stone column standby with history

Factory high view

Wide storage

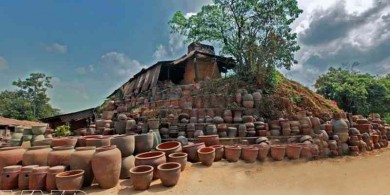

According to National Highway 1A, tourist from Ho Chi Minh city to Dong Nai bridge then turn left, go straight about 1km to Tan Van creamics village – the most famous traditional handicraft village in Dong Nai.

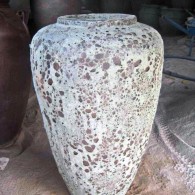

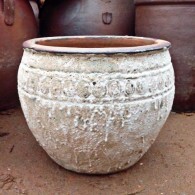

The first ceramics manufacturer in Tan Van was built in 1878, then it became a village gradually where speicalized in producing jar, vases to provide the citizens in Mekong Delta and Binh Thuan, Phu Quoc where do fish sauce job.

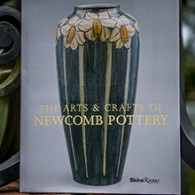

Many Vietnamese people work in ceramics job and have worked for years, but Bien Hoa art pottery was born when Bien Hoa school was established (1903). It’s now the College of Decoration Arts. Two French professors Robert and Mariette Balick was a great success in keeping the indentify of traditional local ceramics on the basis of science: weighing glaze accuately determined kiln of tempature by fire clock, impring quality of ceramics, training skilled students.

The art ceramics in Bien Hoa was exhibited in many countries, awarded many medals, awards of honor in France, Kapan, Thailand, Indonesia, Cambodia, Reunion. Bien Hoa is also the birthplace of modern art ceramics (1963) by Mr Le Ba Dang – the former professor of Practical Art School in Bien Hoa.

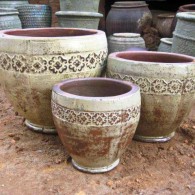

Today, there are many manufacturers in Tan Van, Buu Hoa, Hoa An. Bienhoa art ceramics has spread to Binh Duong, Ho Chi Minh, Vinh Long in 3/4 of century.

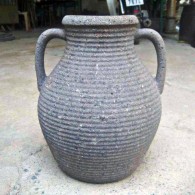

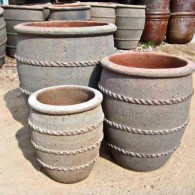

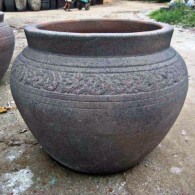

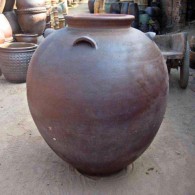

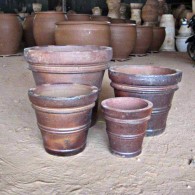

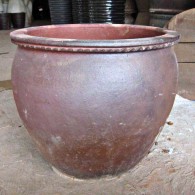

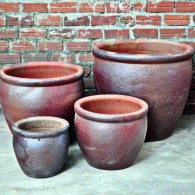

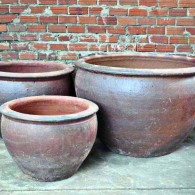

Visitors who visit Tan Van ceramics village will see the manufacturing processes and products in Phong Son ceramics manufacturer. The factory has operated 4 generations, specializes in manufacturing black ceramics exported to Euro, Japan, Thailand, USA…. Here, visitors will be free to explore your artstic talents through the works of ceramics made by yourself.

The production of black ceramics on a general process as follow:

1. Choose different kinds of clay, mixed together, then put clay into machine to mill clay again until it is smooth & soft.

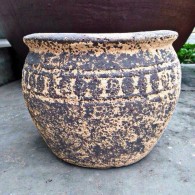

2. Depending on the product which can be made by molds or hand-made the indoor square small pots which need detailed patterns which must use molds. Out door prodcts with simple patten are make entirely by hand. Hand-made products are made from bottom to top.

3. Products are droed under natural sunlight or in the druing-room by 2 days. The fire product in 4 days or more (depend on product size).

4. The final step: make products glossily, not rough on the plane.

…